Health Care

Warp-10: Biotech’s First Mass-Timber Biomedical Plant Goes Where Few Have Gone Before

Inspired by Star Trek’s Warp 10—the theoretical speed limit of the universe—United Therapeutics gave its latest North Carolina construction project the same name, signaling the company’s commitment to pushing boundaries with sustainable construction. The Warp-10 project may not bend space and time, but it is intended to accomplish something unprecedented for the life sciences sector: a Current Good Manufacturing Practices (cGMP) pharmaceutical manufacturing plant built largely in mass timber and designed to drive toward zero carbon. The project demonstrates that wood systems can help realize project goals—even for risk-averse industries constructing technically demanding facilities.

Warp-10

Mission-Driven Low-Carbon Design: United Therapeutics’ Turn to Mass Timber Marks an Industry Milestone

For United Therapeutics, sustainability is inseparable from its patient-centered mission; the multibillion-dollar biotechnology company with roughly 1,400 employees is focused on developing therapies for rare and life-threatening diseases. “As a public benefit corporation, we balance the interests of patients, employees, and the environment alongside the financial interests of our shareholders,” says Andrew Campbell, the company’s Associate Director of Corporate Real Estate. That ethos drove the company to pursue mass timber for Warp-10, its new cGMP manufacturing facility currently being constructed in Research Triangle Park, North Carolina. “The choice to go with mass timber for both the core structure and the envelope of the building was central to making big cuts in our footprint and targeting zero embodied carbon,” Campbell says. “We didn’t want just a pretty mass timber lobby—we wanted as much of the building as possible in wood to truly move the carbon needle. It reflects our broad ambition to operate sustainably.”

Constructing this type of building with mass timber marks a milestone for the industry. Typically built with steel and concrete, a cGMP-compliant facility—cGMP stands for Current Good Manufacturing Practices—must meet FDA standards that ensure pharmaceutical products are consistently produced and controlled to strict quality requirements. These regulations cover everything from facility design and cleanliness to equipment, training, documentation, and process validation.

Warp-10

Warp-10

From Biotech to Biophilia: Mass Timber Creates a Workplace of Choice

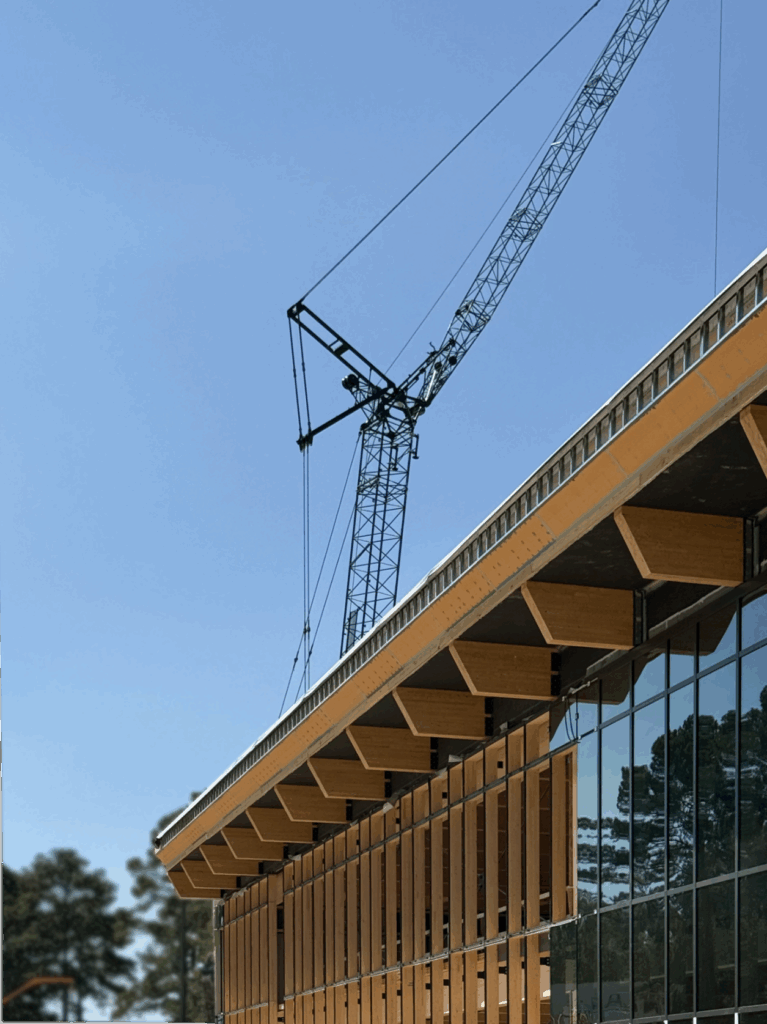

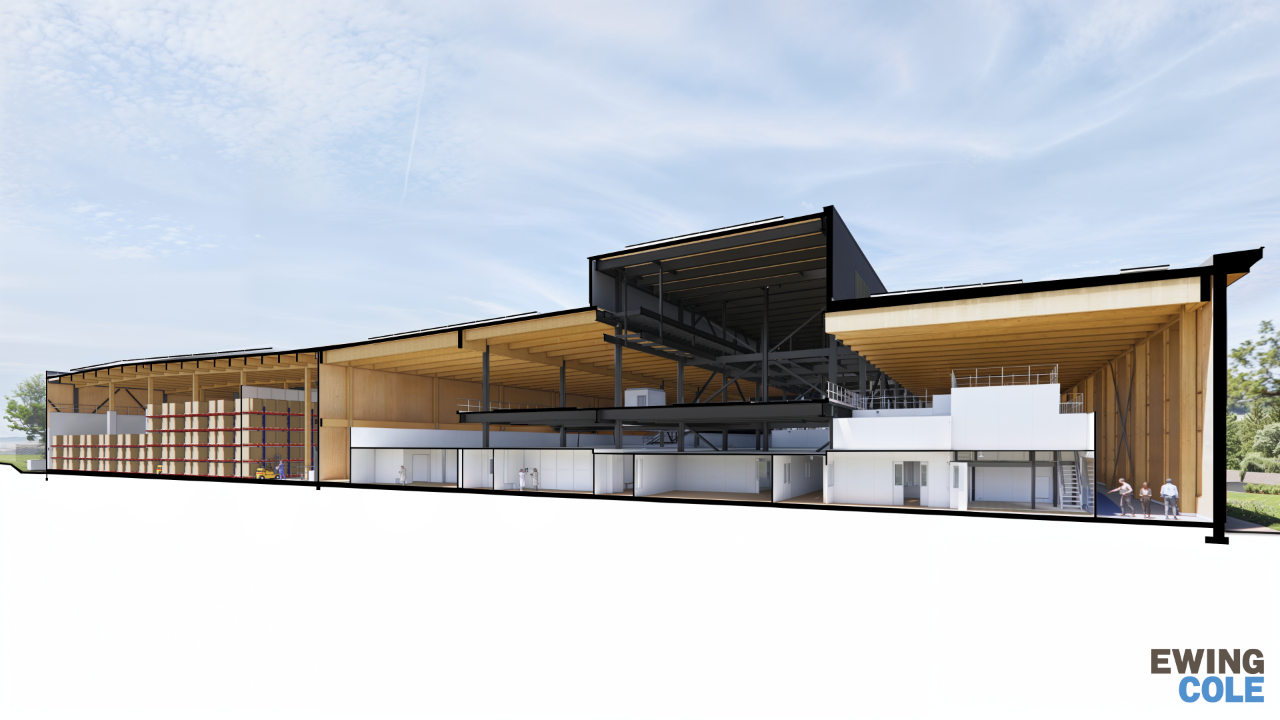

The Warp-10 facility uses a hybrid mass timber structural system to meet those guidelines. Glulam columns and beams form the primary frame, chosen for their strength and ability to handle the long spans required in a manufacturing environment. Cross-laminated timber (CLT) is used for roof and floor decking, as well as wall panels that form the building envelope. Even the curtain wall system that overlays the panels incorporates timber elements, complemented by Shou Sugi Ban siding and bands of Cor-ten steel at the base.

Campbell notes that mass timber offers multiple advantages for a project like Warp-10. Prefabricated components meant the structure could go up much faster than conventional steel and concrete, while sustainably sourced wood helped reduce embodied carbon by locking in the carbon absorbed during growth. He also notes that mass timber delivers comparable strength to concrete at a fraction of the weight, achieves fire resistance through predictable charring, and supports biophilic design strategies that bring natural warmth into the workplace.

Prefabrication played a crucial role: Nordic Structures CNC-cut openings for services and connections before delivery, allowing the structure to assemble “like a building block set,” as Campbell describes it—enabling faster erection and tighter coordination of connections. The Type V-B construction classification permitted the use of combustible materials in a large-floorplate facility, with fire resistance achieved through member sizing and charring allowances.

Warp-10

For occupants, the experience of the building is shaped by exposed wood and deliberate connections to the surrounding North Carolina landscape. Staff will enter the facility via an elevated “Tree Walk” platform that leads into a two-story lobby defined by mass timber staircases, branding elements, and structural members left proudly visible. “Even the UT logo and branding are all constructed out of wood elements, really leaning into wood as a primary material of construction,” says Jennifer Wampler, principal at EwingCole and project architect. Beyond the lobby, a two-level office delivers a mix of workstations and private offices lined with mass timber and softened with acoustic baffles.

Circulation corridors double as 40-foot-high viewing galleries, allowing visitors and employees to look into the cleanroom suite while still experiencing the warmth of natural light and the mass timber structure. This juxtaposition—precisely controlled clean-room environments set against open, timber-framed offices and circulation spaces—turns the building into a kind of living demonstration of how organic structural wood can be integrated into complex cGMP manufacturing facilities with stringent performance requirements. When complete, the facility will manufacture and package dry powder drug products for inhalation, as well as assemble and package delivery devices used with those therapies. It’s designed to support up to around 50,000 patients annually once operational.

Visitors and employees can see the facility at work while also experiencing the spatial warmth, daylight, and material honesty of wood and its biophilic benefits. “The views from within the manufacturing space are unique,” Wampler says. “Vertical fenestration breaks up the horizontal massing, but more importantly, it connects occupants to the surrounding forested campus—making those outlooks both distinctive and special.”

Warp-10

Warp-10

From Forest to Pharma: How Mass Timber Can Meet the Demands of Biotech Manufacturers

Bringing mass timber into a tightly regulated pharmaceutical environment required careful planning. Clean rooms and labs, where organic building materials (including exposed wood) are prohibited, were set in wide structural bays within the larger structure and physically separated from the building’s exposed mass timber structure by perimeter corridors to avoid wood columns impinging on the regulated space. “Within the footprint of the clean room, any of the columns are actually steel columns, enclosed in clean room panels,” Campbell says. “That clear dividing line was critical.”

For Wampler, this approach solved regulatory concerns while also improving flexibility: “Not only have we separated the lab environment from the mass timber, but we also created free-and-clear floor space so that there’s ultimate versatility if it needed to be reconfigured for [different] equipment.” The result is a facility where wood is a defining material in the lobby, offices, and circulation areas, while cGMP zones meet the sterility and adaptability demanded by pharmaceutical production.

Warp-10

It’s a design that proves the viability of wood construction for facilities of this type—reducing environmental impact while offering long-term value. By combining mass timber with lower-carbon concrete and steel, the team reports a net-negative embodied-carbon result when accounting for biogenic carbon stored in the timber. The mass timber structure alone stores about 3,300 metric tons of CO2, helping counterbalance emissions from concrete, steel, and other systems. That’s roughly equivalent to removing 770 gas-powered vehicles from the road for a year.

“We found that even targeted specification changes—like choosing a lower-carbon material or optimizing a structural system—can cut carbon significantly with only marginal impacts on cost,” Wampler says. “When you look at it through the lens of carbon accountability and long-term value, those design decisions deliver a high return.”

While cutting carbon and doing what’s right is a big driver for using mass timber, Campbell also sees it as a way to draw top talent and push the industry forward. “At United Therapeutics, we are focused on scientific innovation that is going to significantly improve lives,” he says. “We are providing proof that a biotech can develop best-in-class therapies for historically neglected diseases, push the envelope for scientific innovation, prioritize patients and the planet, and drive shareholder value at the same time. This is what makes us different and why people want to work here.”

Warp-10

Moving Toward a Mass Timber Future

Beyond Warp-10, mass timber is becoming a go-to material across United Therapeutics’ portfolio. The company operates roughly 20 facilities across North America, ranging from advanced R&D labs in New England to a net-zero office building in Silver Spring, Maryland, and a xenotransplantation research facility in Virginia. Warp-10 is the company’s first major mass timber manufacturing facility—but likely will not be its last.

Campbell says, “You’ll see a lot of ‘no’s’ in your life when you try things like this. People will tell you why you can’t—until they see you do it. Then it becomes, ‘Well, I think we can do this too.’” He adds, “The reality is the more people that undertake projects like this, the more you’ll start to see it in mainstream development. Hopefully this starts to push that groundswell within the industry of just showing what can be done.”

Warp-10

Project Details

- Name:

- Warp-10

- Location:

- Research Triangle Park, Durham, NC

- Owner/Client:

- Architect/Design Team:

- General Contractor:

- Timber Products:

- Hybrid

- Size:

- 196,000 square feet