Commercial

Biotech Meets Biophilia in Mass Timber Lab

At first glance, it’s easy to mistake Adimab’s biotech addition in the forests of New Hampshire for a woodland retreat or a tranquil spa, rather than its true program: a cutting-edge science and research facility. Clad in cedar slats and nestled among the trees, the mass timber structure provides a master class in nature for the scientists performing groundbreaking antibody discovery within—in spaces that are anything but cold or clinical. Designed by Sylvia Richards Practice for Architecture, this 27,000-square-foot building challenges typical lab typologies by weaving together biophilic design, sustainable wood construction, and a poetic but restrained material sensibility. It’s not just a high-performance science building—it’s a human-centered workplace that invites calm, clarity, and connection.

Adimab Office and Laboratories

Adimab Office and Laboratories

Natural Order: A Zen Workplace

for Scientific Discovery

“I had been working with Adimab—a biotech company specializing in antibody discovery—on smaller projects, and in 2022 they were bursting at the seams. The emergency brief, in essence, was: We’re growing rapidly and need more of what we have—a lot more,” Richards says. “But what emerged was more than just an expansion. It was a rethinking of what a laboratory and a workplace for scientific research could be.”

Probing further with her client, Richards learned that beyond more space, the sustainability-minded biotech company wanted a workplace that could attract top talent and reflect its mission to promote ecological and human health.

That started with ensuring a light touch on the surrounding land, preserving as much nature as possible while constructing the new facility to complement an existing lab and warehouse. “We agreed from the beginning that we would disturb as little of the landscape as possible,” Richards says. “The site is rich with wetlands and mature trees, and once we stepped onto it, it was clear we had to thread the building in with precision. So we digitally mapped every rock, every tree, every contour of the wetland to avoid unnecessary impacts. That data informed a route that could weave through the site without removing a single tree unnecessarily.”

The first step in this approach was an elevated walkway accessing the main entrance. The 182-foot Cor-ten steel ramp bridges a 9-foot elevation change and a 120-foot distance between parking and building. More than a catwalk, it becomes a ceremonial entry—a transition between forest and lab, between natural quiet and scientific focus.

This sensitive approach continues in the facility’s orientation and layout. “The building feels dropped into the forest,” Richards says. “We were very intentional about connecting occupants with the natural setting.” Strategic window placement creates cross views and ensures constant glimpses of the surrounding woods and vegetation for the scientists working within.

Adimab Office and Laboratories

Adimab Office and Laboratories

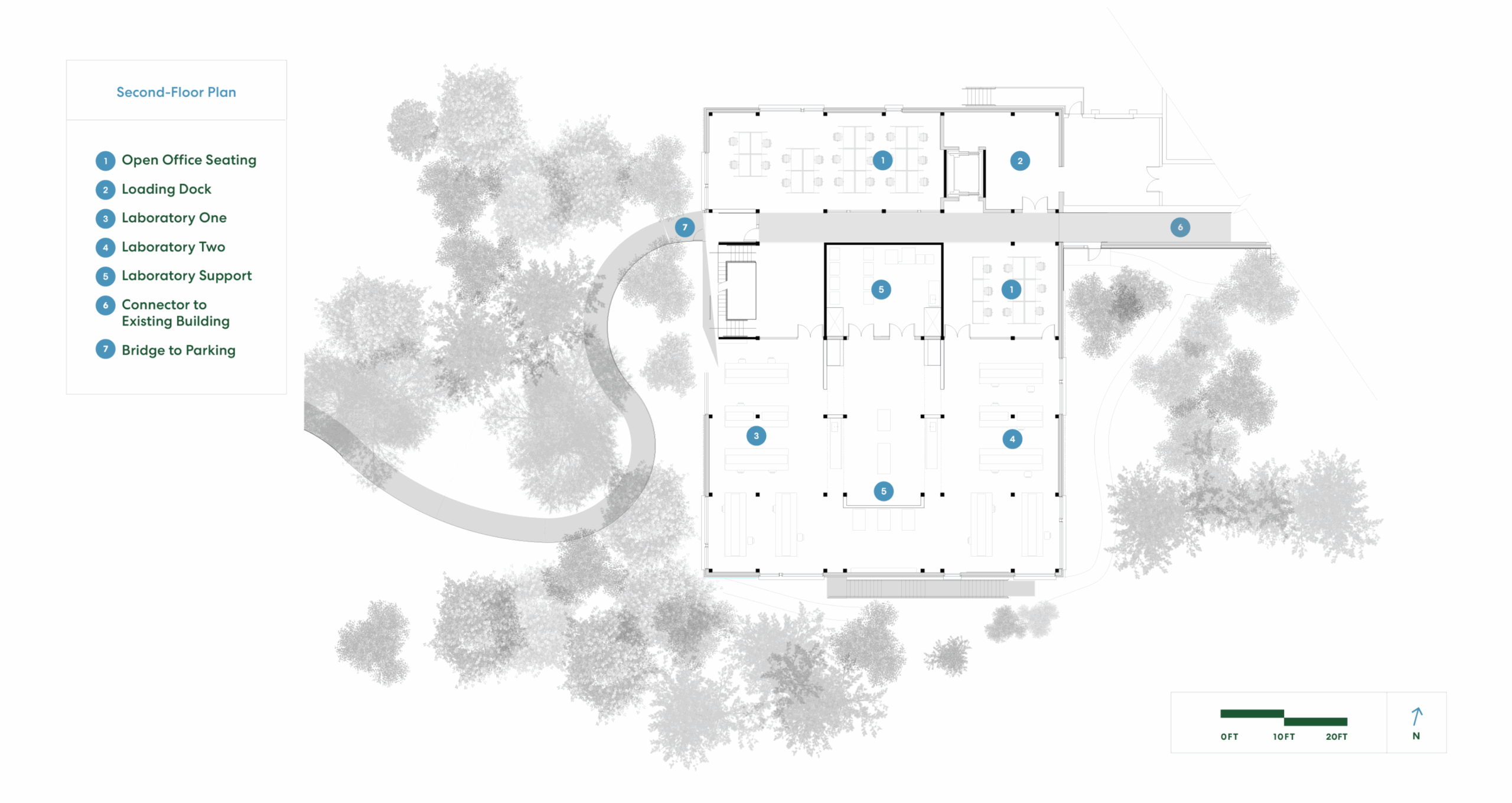

Entering from the west, those scientists arrive on the second floor—the main level of the three-story, nearly all-wood building—and are immediately surrounded by exposed cross-laminated timber (CLT). Upon entry, a clear visual axis connects them to an existing building via a glazed corridor to the east. A skylit staircase anchors the circulation, encouraging easy movement between levels.

This main level is the heart of scientific activity: It houses two primary laboratories (Lab One and Lab Two), supported by adjacent lab support spaces and a discreetly placed loading dock. Lining the southern façade is a generous open-office area where employees work in a mingled, non-hierarchical layout. Wood, daylight, and curated views imbue the space with a quiet sense of order—a lab designed not just for performance, but for tranquility and focus.

The third floor serves as the social and collaborative heart of the building—an elevated suite of meeting rooms, open workspaces, and all-hands gathering areas that feel more like treehouses than boardrooms. Floor-to-ceiling glass wraps corner conference rooms, prompting a mid-construction design shift: Instead of traditional conference tables, these rooms now feature bright yellow sofas and custom coffee tables made from leftover fabrication scraps. At the center of the floor is a column-lined meeting area employees call “The Bema”—a nod to a forest amphitheater at nearby Dartmouth College. Quiet but not sterile, the space is softened by wool acoustic panels and origami-like ceiling forms that temper sound without muting the visual warmth of the exposed mass timber structure.

Adimab Office and Laboratories

Adimab Office and Laboratories

Wood Science: How Mass Timber Can

Meet the Rigorous Demands

of Laboratory Design

Beneath the biophilic design lies a precise technical backbone—one that proves mass timber can meet the stringent demands of a high-performance lab. Although at first mass timber may seem to be a less-likely choice for a laboratory and research facility, it is a structural system, as Richards points out, that is actually very well suited for the demands of this building type.

“You might assume you have to sacrifice performance to use mass timber in a lab, but that’s just not true,” Richards says. “This building fully functions with all the technical requirements—air handling, vibration control, everything—while still showcasing the beauty of the material.”

The building uses a combination of glulam columns and beams and CLT panel floor plates. This system supports a three-story structure with open, beam-free corridors for mechanical, electrical, and plumbing (MEP) systems. It allowed most MEP systems to run unobstructed, reducing the need for penetrations through beams and walls or for lowered ceilings.

Adimab Office and Laboratories

“We created dedicated corridors above the beams for the essential systems and tucked everything away cleanly, so the infrastructure doesn’t clutter the space,” Richards says. “And all of the core technical services reside on the ground floor, so we weren’t feeding things above, as you have to do in some labs.”

Interior CLT bearing and shear walls were used selectively, alongside post-and-beam construction, to support the structure. Mass timber’s built-in fire protection eliminated the need for encapsulation and allowed for maximum wood exposure. These CLT walls also supplemented non-load-bearing exterior light-frame shear walls designed to resist lateral forces. CLT panels and plywood splines form the structural diaphragm, avoiding the need for a thicker structural concrete slab. A concrete topping on the CLT floor plates was selected to meet acoustic and vibration performance goals, ensuring the facility meets the stringent requirements of a biotech laboratory; the concrete-topped CLT decking is overlaid with white oak flooring in the common areas, and with natural wool carpeting in most meeting rooms and offices.

“While mass timber was first and foremost chosen for its environmental benefits, the client was really impressed with just how efficient and high tech mass timber can be,” Richards says. “The structure went up in a matter of weeks. This is no log cabin. It’s a highly refined, advanced material. They just loved that this building could resonate with both its unique setting and the company’s mission.”

Adimab Office and Laboratories

Project Details

- Project Name:

- Adimab Office and Laboratories

- Location:

- Lebanon, NH

- Primary Architect:

- Collaborating Project Architect:

- Owner:

- General Contractor:

- Structural Engineer:

- Mass Timber Supplier:

- Size:

- 27,800 square feet

- Mass Timber Installer:

- Timber Products: