Single-Family Home

Could mass timber reinvent production home building?

With a background in architecture and commercial real estate development, Nashville, Tennessee-based Justin Koziol is looking to create a different model for production home builders: “We’re taking the production home building business model and applying modular construction using CLT in order to deliver sustainable, high-performance homes,” he says.

Aera Homes

Aera Homes

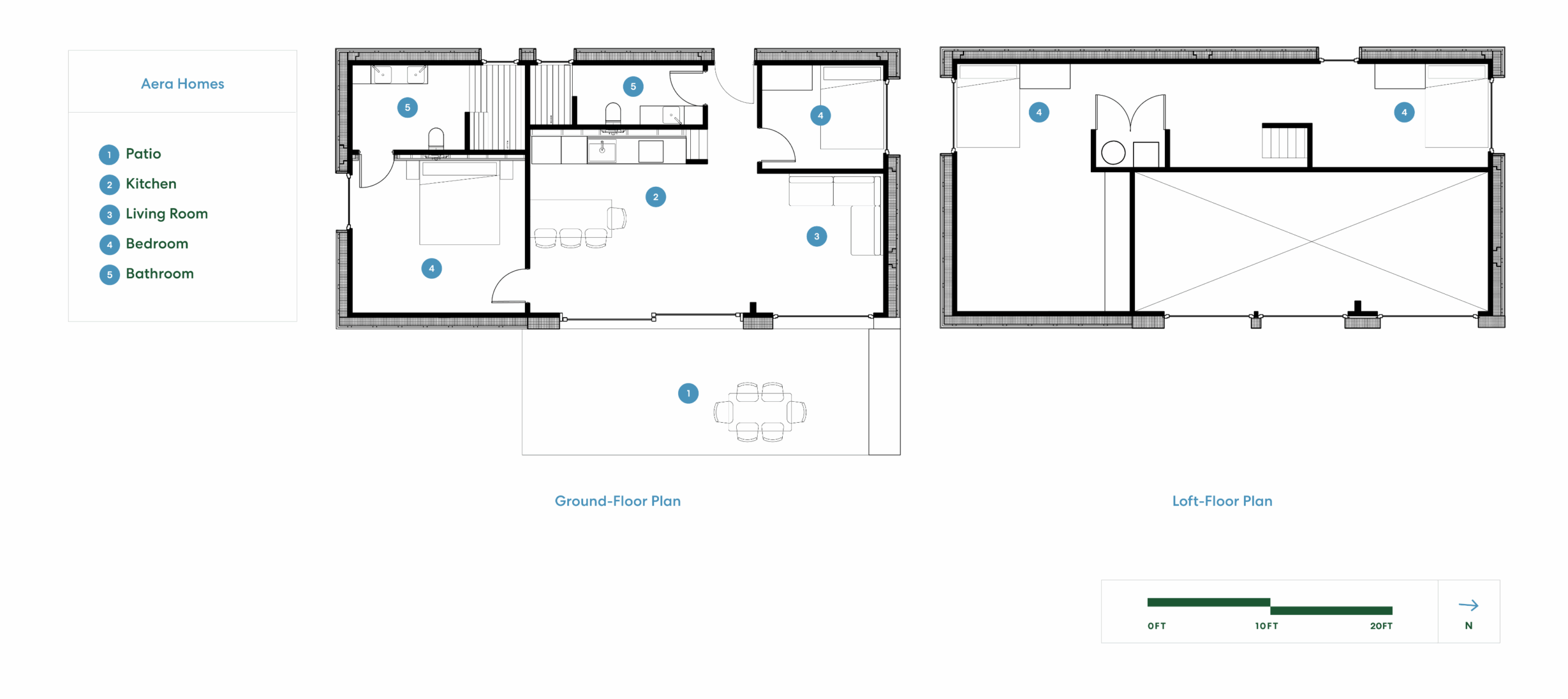

Koziol’s company, Aera Systems, completed its first home in the Waters Edge community south of Nashville. The 900-square-foot, three-bedroom, two-bath house combines three factory-built mechanical “pods”—bathroom, kitchen, and utility areas prefinished with plumbing, electrical, fixtures, and flooring—and then adds

CLT panels to enclose the home, creating the bedrooms and living spaces. The compact home is roughly 21 by 43 feet with living and dining rooms and a kitchen in an open, double-height space. A primary bedroom and bathroom and a guest bedroom and bath are located on the ground level; the second floor—accessed by a ship’s ladder that’s incorporated into the galley kitchen—has an additional bedroom and study space. The simple assembled volume is enclosed under an insulated metal panel shed roof.

Aera Homes

Aera has adopted what Koziol calls a “pod and panel approach” that limits the size of each piece to avoid shipping oversized loads. “We wanted to avoid [one of] the downfalls of modular construction, which is the logistics challenge of shipping really big things,” Koziol says.

The mechanical core of the home comprises three distinct pods—guest bathroom + kitchen pod, master bathroom pod, and mechanical pod—that are built and finished in the Nashville facility. The largest pod is 12 feet wide and contains the bathroom and kitchen. The accompanying CLT panels are fitted in the shop with windows and doors, including an expansive 25-foot-long sliding door.

Aera Homes

Aera Homes

Aera Homes

Sustainable and scalable

Mass timber is critical to achieving Aera’s sustainability goals: to produce a neutral embodied carbon house. But using CLT will also allow Aera to scale the production by replacing the many pieces that go into a stick-frame wall with a single panel: “It’s really hard to scale the manufacturing of stick-built construction,” Koziol says. The Aera Home’s mass timber elements are produced by Illinois- and Texas-based Sterling Structural using Southern Yellow Pine. “[CLT] gives you a really awesome envelope,” Koziol says. “You have complete exterior insulation. It’s solid wall construction, so there’s nothing that can go wrong in the cavity of the wall.” Outside, the Waters Edge project is clad in a locally sourced cedar, but Koziol notes that Aera uses a rain screen system that can accommodate any number of finishes.

Aera Homes

Aera Homes

The prefab approach leads to improved speed of construction in the field. “We typically go from ‘the slab is ready’ to ‘the house is dried-in’ in less than seven working days,” Koziol says. That includes a complete enclosure with roof, windows, and doors in place. The overall construction process spans about two months, including roughly 30 days of prefabrication in the factory and 30 days in the field.

Initially, Aera isn’t doing any custom homes, although there are opportunities for some customization down the road. For now, Aera has one model of prefab home—the one erected in Waters Edge.

But there are bigger plans for the future: “We’re integrated as the developer, the builder, [and] the modular manufacturer,” Koziol says. All of Aera’s prefabrication is currently being done in the prototype facility in Nashville. “We’re in a relatively small facility, so we can do about 20 to 25 homes a year out of this spot.” But Koziol hopes to become a national home builder with a short-term goal of producing 200 to 300 homes a year within five years—eventually opening facilities in other regions to produce seven to eight thousand homes each year. At a scale that would place Aera among the 20 largest builders in the U.S., it’s a vision that would place prefabricated mass timber homes at the center of addressing the national housing shortage.

Aera Homes

Aera Homes

Project Details

- Project Name:

- Aera Homes

- Location:

- Nashville, TN

- Architect/Developer:

- Size:

- 900 square feet

- Timber Products: