Project Gallery: Wood Architecture + Design

Some sites for more eyes.

Select project types that apply and we’ll cross reference our library to show you what we have.

Type

-

Education

EducationGrafton Architects’ Anthony Timberlands Center Is a Story Book of Timber

-

Health Care

Health CareWarp-10: Biotech’s First Mass-Timber Biomedical Plant Goes Where Few Have Gone Before

-

Light-Frame Construction, Single-Family Home

Light-Frame Construction, Single-Family HomeMiller Hull’s Light-Frame Cabin Has a Light Touch on the Land

-

Civic Community

Civic CommunityBora’s Holgate Library and Mass Timber Are a Natural Fit

-

Single-Family Home

Single-Family HomeCould mass timber reinvent production home building?

-

Civic Community

Civic CommunityTekαkαpimək Contact Station Unites Wood, Forest, and Landscape

-

Multifamily

MultifamilyMontana Workforce Housing Makes Mass Timber Modular

-

Light-Frame Construction, Multifamily

Light-Frame Construction, MultifamilyWRNS Studio’s Mixed-Use Brickline Demonstrates Light-Frame Advantages

-

Education

EducationLeers Weinzapfel Cultivates Campus Connections at the Davis Center

-

Civic Community

Civic CommunityMuseum’s Authentic Wood Look Tells Jackson Hole’s Story

-

Single-Family Home

Single-Family HomenArchitects’ CLT House Celebrates Wood’s Beauty Inside and Out

-

Commercial

CommercialBiotech Meets Biophilia in Mass Timber Lab

-

Single-Family Home

Single-Family HomeStartup’s Prefab Home Design Has a Carbon-Negative Footprint

-

Education

EducationStudio Gang’s Campus Building Puts Mass Timber and Sustainability on Display

-

Commercial

CommercialAt RIOS’s 42XX, Mass Timber Builds a Better Workday

-

Affordable Housing, Multifamily

Affordable Housing, MultifamilyAfricatown Plaza Draws on a Community’s Vision

-

Mass Timber, Multifamily

Mass Timber, MultifamilyFrame 122 Brings Mass Timber to NYC Homes

-

Education, Mass Timber

Education, Mass TimberA Sound Choice: Mass Timber Strikes the Right Note for Community MusicWorks Center

-

Education

EducationSO – IL’s Williams College Museum of Art Features Mass Timber With a Twist

-

Education, Mass Timber

Education, Mass TimberElevating Play: Mass Timber and Prefab Wood Builds a Better Preschool

-

Civic Community, Mass Timber

Civic Community, Mass TimberARO’s Visitors Center Unites Art, Nature, and Culture

-

Single-Family Home

Single-Family HomeJohnsen Schmaling’s CLT House Is an Elegant Display of Mass Timber’s Beauty

-

Single-Family Home

Single-Family HomeElliptical Alpine Home Leaves a Gentle Footprint with Wood

-

Education, Mass Timber

Education, Mass TimberNADAAA and HDR team up for mass timber architecture school addition

-

Single-Family Home

Single-Family HomeIs Mass Timber the Future of Modular Multifamily Universal Design?

-

Multifamily

MultifamilyMASS Design Group’s senior housing redevelopment fosters resident connections in Boston

-

Civic Community, Mass Timber

Civic Community, Mass TimberGraco Park building leaves a light carbon footprint

-

Commercial

CommercialSalem, Oregon public works building provides a welcoming workplace

-

Commercial

CommercialVerdant LA mixed-use building exposes mass timber for a natural touch

-

Commercial

CommercialProposed 55-story building highlights mass timber’s towering potential

-

Single-Family Home

Single-Family HomeElegant Wood-Clad Exterior Staircase Unites Texas Tree House

-

Civic Community

Civic CommunityCommunity Hub’s Wood Structure Reflects its Tree-Filled Landscape

-

Multifamily

MultifamilyLight and Nimble: Clever Prefab Wood-Frame Development Brings Livability to Nashville’s Germantown

-

Commercial

CommercialBank Designs Link Community and Local Context With Wood Construction

-

Education

EducationStudio Gang’s Kresge College Addition Nestles Wood Construction in Forested Landscape

-

Single-Family Home

Single-Family HomeCedar-clad home balances modern form with rustic wood framing

-

Frame 122 Brings Mass Timber to NYC Homes

-

Single-Family Home

Single-Family HomeCarbon-Negative Home Goes All-Natural With Mass Timber and Renewable Materials

-

Education

EducationArchitecture School Expansion Uses Timber as Teaching Tool

-

Civic Community

Civic CommunityGame Changer: San Antonio Spurs’ Mass Timber Practice Facility the First of its Kind

-

Education

EducationBowdoin College’s Mass Timber Buildings Support Its Carbon-Neutral Approach

-

Education

EducationNew Mass Timber Student Housing Demonstrates a Commitment to Sustainability

-

Hospitality, Light-Frame Construction, Mass Timber

Hospitality, Light-Frame Construction, Mass TimberHip Hotel Tackles Taxing Terrain with Mass Timber

-

Light-Frame Construction, Single-Family Home

Light-Frame Construction, Single-Family HomeCedar-Clad Home Embraces Its Forest Surroundings

-

Civic Community, Light-Frame Construction

Civic Community, Light-Frame ConstructionNorwegian-American Museum Addition Features a Majestic Glulam Entrance

-

Commercial, Mass Timber

Commercial, Mass TimberAmazon’s HQ2 Creates Community While Crunching Carbon

-

Single-Family Home

Single-Family HomeHow Lake | Flato Enhanced a Long Island Home with Prefab Wood

-

Education, Light-Frame Construction, Mass Timber

Education, Light-Frame Construction, Mass TimberTimber Tutelage at The Ecology School

-

Civic Community, Light-Frame Construction

Civic Community, Light-Frame ConstructionThe Centennial Park Pavilion Is Fayetteville, Arkansas’s Newest Landmark

-

Civic Community

Civic CommunityRice University’s Mass Timber Pavilion Celebrates Its Natural Landscape

-

Light-Frame Construction, Single-Family Home

Light-Frame Construction, Single-Family HomeWorrell Yeung’s North Salem Farm Honors the Archetypal Wood-Clad Barn

-

Commercial

CommercialPortland Firm’s All-Wood HQ Shows Beauty and Versatility of Mass Timber

-

Commercial, Light-Frame Construction, Single-Family Home

Commercial, Light-Frame Construction, Single-Family HomeJohnsen Schmaling Reimagines the Wood Deck for Urban Outdoor Living

-

Civic Community

Civic CommunityCommunity Library Showcases Airy Light-Frame Wood Construction

-

Affordable Housing, Mass Timber, Multifamily

Affordable Housing, Mass Timber, MultifamilyGlobeville Affordable Housing & Library

-

Light-Frame Construction, Single-Family Home

Light-Frame Construction, Single-Family HomeSwampy Hollow

-

Civic Community

Civic CommunityMoynihan Connector Timber Bridge

-

Mass Timber, Multifamily

Mass Timber, MultifamilyD.C.’s Largest Mass Timber Multifamily Building Will Put Wood on Full Display

-

Light-Frame Construction, Single-Family Home

Light-Frame Construction, Single-Family HomeFeldmann Residence

-

Mass Timber, Multifamily

Mass Timber, MultifamilySuperBungalows

-

Commercial, Mass Timber

Commercial, Mass TimberHouston Endowment Headquarters

-

Affordable Housing, Civic Community, Multifamily, Sustainability

Affordable Housing, Civic Community, Multifamily, SustainabilityNesika Illahee Affordable Housing

-

Mass Timber, Multifamily

Mass Timber, MultifamilyWilson Forest Park Townhomes

-

Education, Hospitality, Mass Timber

Education, Hospitality, Mass TimberTony and Libba Rane Culinary Science Center

-

Education, Mass Timber, Sustainability

Education, Mass Timber, SustainabilityFounders Hall

-

Civic Community, Sustainability

Civic Community, SustainabilityThe Mercury Store

-

Light-Frame Construction, Mass Timber, Single-Family Home

Light-Frame Construction, Mass Timber, Single-Family HomeMatt’s Place Demonstration Project

-

Commercial, Mass Timber, Multifamily, Tall Wood

Commercial, Mass Timber, Multifamily, Tall WoodAscent

-

Civic Community, Mass Timber

Civic Community, Mass TimberSarah Campbell Blaffer Foundation Center for Conservation

-

Mass Timber, Multifamily

Mass Timber, MultifamilyRailyard Flats

-

Affordable Housing, Multifamily

Affordable Housing, MultifamilyFreedom House

-

Commercial, Mass Timber

Commercial, Mass TimberOutpost

-

Mass Timber, Multifamily, Tall Wood

Mass Timber, Multifamily, Tall WoodINTRO

-

Hospitality

HospitalityHotel Magdalena

-

Education

EducationAndy Quattlebaum Outdoor Education Center

-

Commercial

Commercial80 M Street

-

Light-Frame Construction, Single-Family Home

Light-Frame Construction, Single-Family HomeDetroit Eco Homes

-

Mass Timber, Multifamily

Mass Timber, MultifamilyTimber Lofts

-

Civic Community, Sustainability

Civic Community, SustainabilityLubber Run Community Center

-

Affordable Housing, Mass Timber, Multifamily

Affordable Housing, Mass Timber, MultifamilyWessex Woods

-

Commercial, Mass Timber

Commercial, Mass TimberSideyard

-

Commercial, Mass Timber

Commercial, Mass TimberPlatte Fifteen

-

Commercial, Mass Timber, Multifamily, Sustainability

Commercial, Mass Timber, Multifamily, SustainabilityBullitt Center

-

Commercial, Mass Timber, Sustainability

Commercial, Mass Timber, SustainabilityMountain Equipment Co-op Headquarters

-

Multifamily

MultifamilyBrooklyn Riverside

-

Affordable Housing, Multifamily, Sustainability

Affordable Housing, Multifamily, SustainabilityYobi Microhousing

-

Multifamily

MultifamilyMOTO

-

Multifamily

MultifamilySolaire Wheaton

-

Multifamily

MultifamilyCrescent Terminus

-

Multifamily

MultifamilyMarselle Condominiums

-

Multifamily

MultifamilyWREN

-

Multifamily, Sustainability

Multifamily, SustainabilityKiln Apartments

-

Mass Timber, Multifamily, Tall Wood

Mass Timber, Multifamily, Tall WoodOrigine

-

Mass Timber, Multifamily, Sustainability, Tall Wood

Mass Timber, Multifamily, Sustainability, Tall WoodArbora

-

Mass Timber, Multifamily

Mass Timber, MultifamilyLegacy on Park Avenue

-

Affordable Housing, Multifamily, Sustainability

Affordable Housing, Multifamily, SustainabilityOrchards at Orenco

-

Mass Timber, Multifamily, Tall Wood

Mass Timber, Multifamily, Tall WoodCarbon12

-

Multifamily

MultifamilyStella Apartments

-

Commercial, Multifamily

Commercial, MultifamilyEmory Point

-

Civic Community, Mass Timber

Civic Community, Mass TimberBiomass Boiler Building

-

Commercial, Mass Timber, Sustainability

Commercial, Mass Timber, SustainabilityBC Passive House Factory

-

Commercial, Mass Timber

Commercial, Mass TimberStructureCraft Facility

-

Commercial, Mass Timber, Sustainability

Commercial, Mass Timber, SustainabilityMcDonald’s Global Flagship in Chicago

-

Health Care, Mass Timber, Sustainability

Health Care, Mass Timber, SustainabilityNorth Bay Regional Health Centre

-

Health Care, Mass Timber, Sustainability

Health Care, Mass Timber, SustainabilityHerrington Recovery Center

-

Multifamily

MultifamilyArena District Apartments

-

Education, Mass Timber, Tall Wood

Education, Mass Timber, Tall WoodBrock Commons Tallwood House

-

Education, Mass Timber

Education, Mass TimberU of W Mercer Court / Elm Hall

-

Education, Mass Timber

Education, Mass TimberJacobson Hall Student Housing at Trinity Western University

-

Education, Mass Timber

Education, Mass TimberScott Family Amazeum

-

Education, Mass Timber, Sustainability

Education, Mass Timber, SustainabilityThe R.W. Kern Center at Hampshire College

-

Education, Mass Timber, Sustainability

Education, Mass Timber, SustainabilityWood Innovation and Design Centre

-

Education, Mass Timber, Sustainability

Education, Mass Timber, SustainabilityWood Innovation Research Lab

-

Education, Mass Timber, Sustainability

Education, Mass Timber, SustainabilityCentre for Interactive Research on Sustainability

-

Education, Mass Timber, Sustainability

Education, Mass Timber, SustainabilityCommon Ground High School

-

Education, Mass Timber, Sustainability

Education, Mass Timber, SustainabilityUMass Amherst Design Building

-

Education, Mass Timber

Education, Mass TimberMartha C. Cutts Gymnasium

-

Education, Mass Timber

Education, Mass TimberFranklin Elementary School

-

Education, Mass Timber

Education, Mass TimberDuke Lower and Middle Schools

-

Education, Mass Timber

Education, Mass TimberEl Dorado High School

-

Education, Mass Timber

Education, Mass TimberUBC Earth Sciences Building

-

Education, Mass Timber

Education, Mass TimberMcEwen School of Architecture

-

Civic Community, Mass Timber

Civic Community, Mass TimberTelus Stadium Université Laval

-

Civic Community, Sustainability

Civic Community, SustainabilityMojave Ranger Station

-

Civic Community, Sustainability

Civic Community, SustainabilityVanDusen Visitor Centre

-

Civic Community, Mass Timber

Civic Community, Mass TimberRichmond Olympic Oval

-

Civic Community, Mass Timber, Sustainability

Civic Community, Mass Timber, SustainabilityHitchcock Center for the Environment

-

Civic Community, Mass Timber

Civic Community, Mass TimberArena Stage at the Mead Center for American Theater

-

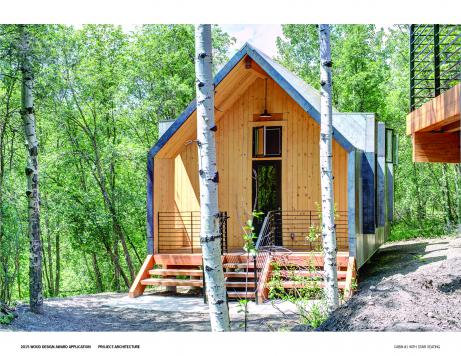

Civic Community, Mass Timber

Civic Community, Mass TimberGirl Scout Cabins

-

Civic Community, Mass Timber

Civic Community, Mass TimberPortland International Jetport

-

Civic Community, Mass Timber

Civic Community, Mass TimberCathedral of Christ the Light

-

Civic Community, Mass Timber

Civic Community, Mass TimberFire Station 76

-

Civic Community, Mass Timber, Sustainability

Civic Community, Mass Timber, SustainabilityMosaic Center for Conscious Community & Commerce

-

Commercial, Mass Timber

Commercial, Mass TimberAlbina Yard

-

Civic Community, Mass Timber

Civic Community, Mass TimberFort McMurray International Airport

-

Civic Community, Mass Timber

Civic Community, Mass TimberMill River Park Carousel Pavilion

-

Civic Community, Mass Timber

Civic Community, Mass TimberThe Barn

-

Commercial, Mass Timber, Multifamily

Commercial, Mass Timber, Multifamily38 Davis

-

Commercial, Mass Timber

Commercial, Mass TimberT3: Timber, Transit, Technology

-

Commercial, Multifamily

Commercial, MultifamilyTemplar Flats

-

Commercial, Mass Timber, Sustainability

Commercial, Mass Timber, SustainabilityButler Square

-

Commercial, Sustainability

Commercial, SustainabilityThe Alliance for Sustainable Colorado

-

Civic Community, Mass Timber

Civic Community, Mass TimberCalgary Central Library

-

Commercial, Mass Timber

Commercial, Mass TimberClay Creative

-

Commercial, Mass Timber

Commercial, Mass TimberFramework 6th Ave Portland

-

Commercial, Mass Timber, Sustainability

Commercial, Mass Timber, SustainabilityThe Hudson

-

Commercial, Mass Timber

Commercial, Mass TimberLive Oak Bank Headquarters

-

Commercial, Sustainability

Commercial, SustainabilityVenture Capital Office Headquarters

-

Commercial, Mass Timber, Sustainability

Commercial, Mass Timber, SustainabilityAutodesk Portland Office

-

Commercial, Mass Timber

Commercial, Mass TimberComplexe Synergia

-

Commercial, Mass Timber

Commercial, Mass TimberAmeublements Tanguay

-

Commercial, Mass Timber

Commercial, Mass Timber2150 Keith Drive

-

Commercial, Mass Timber, Sustainability

Commercial, Mass Timber, Sustainability77 WADE

-

Commercial, Mass Timber, Multifamily, Sustainability

Commercial, Mass Timber, Multifamily, SustainabilityCLT Passive House Demonstration Project